What is Automated Inspection Via CT for the Dental and Medical Sector?

Posted: 25/08/2022

Automated inspection for the dental and medical sector via CT is a fast, cost-effective, precise enabler to superior manufacturing. Synchronized hardware and software collect and analyze data to determine whether an inspected product meets its requirements, while automation eliminates manual activities from the user.

As explored in a previous VJ Technologies White Paper, Automated Inspection for Aerospace via CT, and downloadable via www.vedact.vjt.com, scanning for aerospace operates with specific sensitivity under a strict set of requirements. Automated inspection for the dental and medical industry prioritizes aligning First Article Inspection (FAI) with the appropriate degree of resolution, determined by what a manufacturer is looking to detect. Whether you are First Article inspecting components across the dental or medical sector, capturing the shape, size, and structure of the outer edges is critical.

What makes 3D-CT ideal for scanning aerospace parts?

Aerospace parts tend to be made of dense metal. Components are often manufactured from Inconel—a family of high performance nickel-based alloys—or carbon steel. The aerospace industry comprises parts that vary in scale and thickness, encompassing aspects that move and rotate. Dental and medical manufacturers often require FAI on smaller pieces such as utensils, tools, dental retainers, the EpiPen, and hip implants. By comparison, such apparatus is likely to require lower energy 3D-CT X-ray scanning solutions.

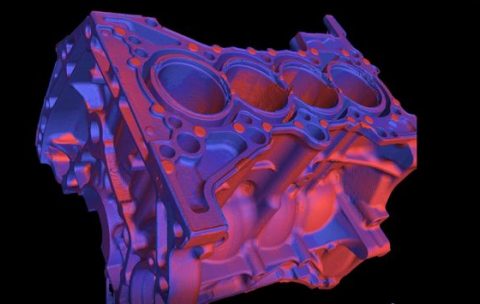

Manufacturers of dental and medical equipment often manufacture working prototypes in their laboratories, using their own machinery. Whether an appliance, tool, element, or mechanism, the part can be 3D-CT scanned to obtain a report that evidences how close the prototype came to their Computer-aided Design (CAD).

To bring FAI to life, while a manufacturer’s labs are economical for making working prototypes, lab-based machines are not built to manufacture hundreds of thousands of parts. Once manufacturers are happy that their FAI meets the prototype’s CAD criteria, machines on the production floor begin replicating the prototype. First Article Inspection is then used again to check the production floor-manufactured part against the FAI lab-made prototype. This process is the difference between scanning for Research and Development (R & D) purposes, including design analysis and prototype validation, and inspecting mass production.

With any luck, the FAI report of a production floor-manufactured part presents the same findings as that of your lab-made prototype as you observe dimensions, parallelism between features, perpendicularity, surface roughness, and anything else that might affect the function or performance of the part.

This is a far cry from optical technologies that only scan the surface of a product.

Automated inspection via 3D-CT examines a part’s inner workings, checking for defects such as cracks, holes, or voids across components. Failings that could be found amid dental instruments, patient retainers, medical prosthetics, and everything in between. Inspection enables design adaptation to ensure parts meet product criteria and adhere to industry standards, like designing turbine blades for aerospace or steering knuckles for automobiles.

It is fair to say that less time might be spent examining a dental impression because such a product has an excellent tolerance to change—meaning that if the impression does not fit perfectly the first time around, adjustments can be made. However, more time might be given to inspecting a hip implant, for example: once implanted into a human body, it has zero-tolerance to further inspection or moderation.

Inspection using Automated Defect Recognition (ADR) via 3D-CT empowers engineers and manufacturers to design and build complex components such as hip joints or dental retainers.

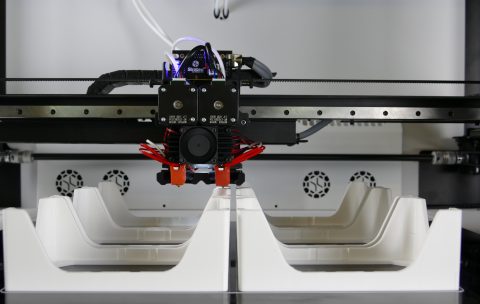

When you combine ADR with Additive Manufacturing—more commonly known as 3D-printing—that uses a manufacturer’s CAD model to construct three-dimensional objects of precision, dentists and medical professionals are enabled to satisfy quality standards, safety regulations, and patients repeatedly.

Share to:

New Paradigm in Additive Manufacturing

Read about the benefits for Computed Tomography for Additive Manufacturing